.png)

Take advantage of

shape memory.

Shape Setting

In order to take full advantage of Nitinol’s shape memory properties, some customers require the wire to be in a certain shape in order to perform in their application. At Fort Wayne Metals, we can “set” a wire shape that specifically conforms to your device design requirements.

Shape setting is the process of wrapping Nitinol wire around a mandrel or fixture and heat treating at a closely controlled time and temperature to achieve a desired shape in the material. After the material is quenched and removed from the mandrel, the wire will “remember” its shape after deformation or a change in temperature.

Fort Wayne Metals has multiple precision fluidized beds as well as other proprietary shape setting methods to meet the needs of any complex design requirements. We also have rapid prototyping capabilities, which allow us to design and fabricate our own tooling in house resulting in greatly improved lead times. Our engineering team has many years of experience in building components to our customers’ specifications.

If your application requires shape set parts, contact us. We also offer shape setting information on the Nitinol Overview Page. We’re one of the world’s leaders in working with Nitinol, and we’re ready to put our expertise to work for you.

Specifications

Product forms available for shape setting:

Wire diameter:

- 0.0762 mm to 2.000 mm [0.003 in to 0.0787 in]

Available surface finishes:

- Natural forming oxide

- Dark oxide

- Etched

- Electropolished

- Surface conditioned

End treatments:

- Coining / Flattening

- EDM

- Weld bead

- Mechanical assemblies

Available inspection methods:

- DSC testing per ASTM F2004

- Active Af testing per ASTM F2082

- Tensile testing per ASTM F2516

- More testing available upon request

.png)

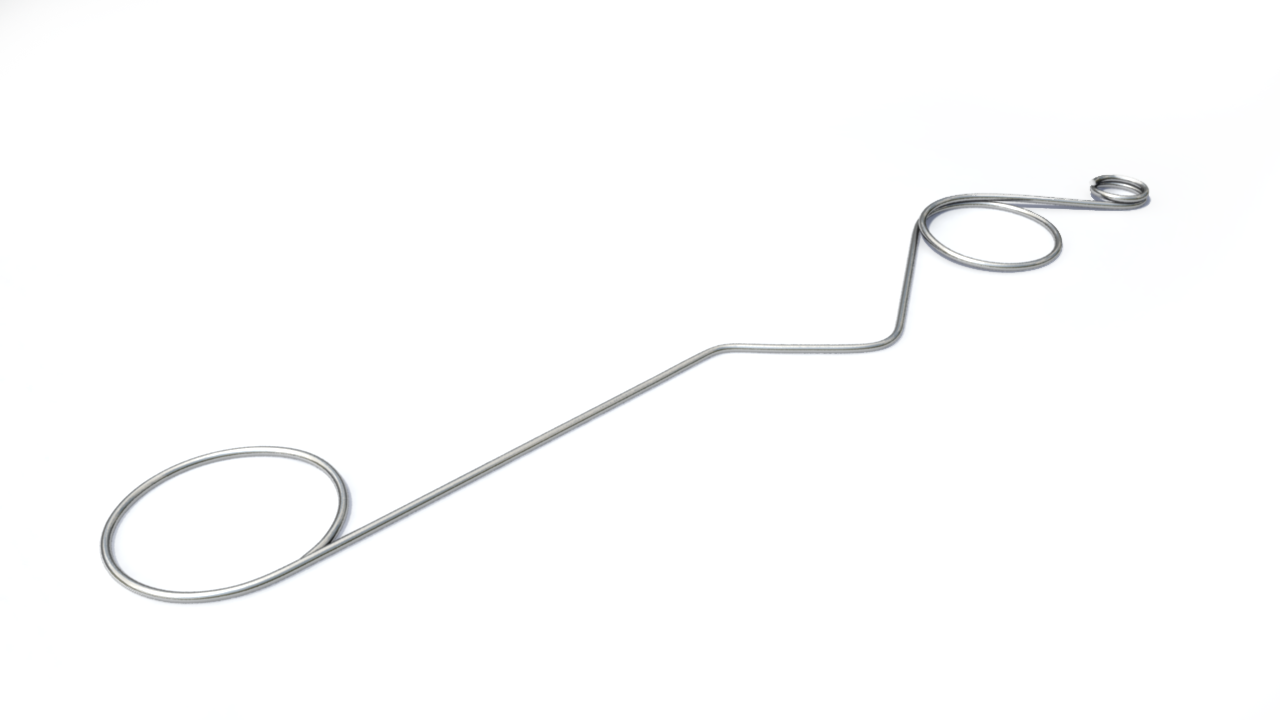

Arrow with coined ends - dark oxide

Complex circles

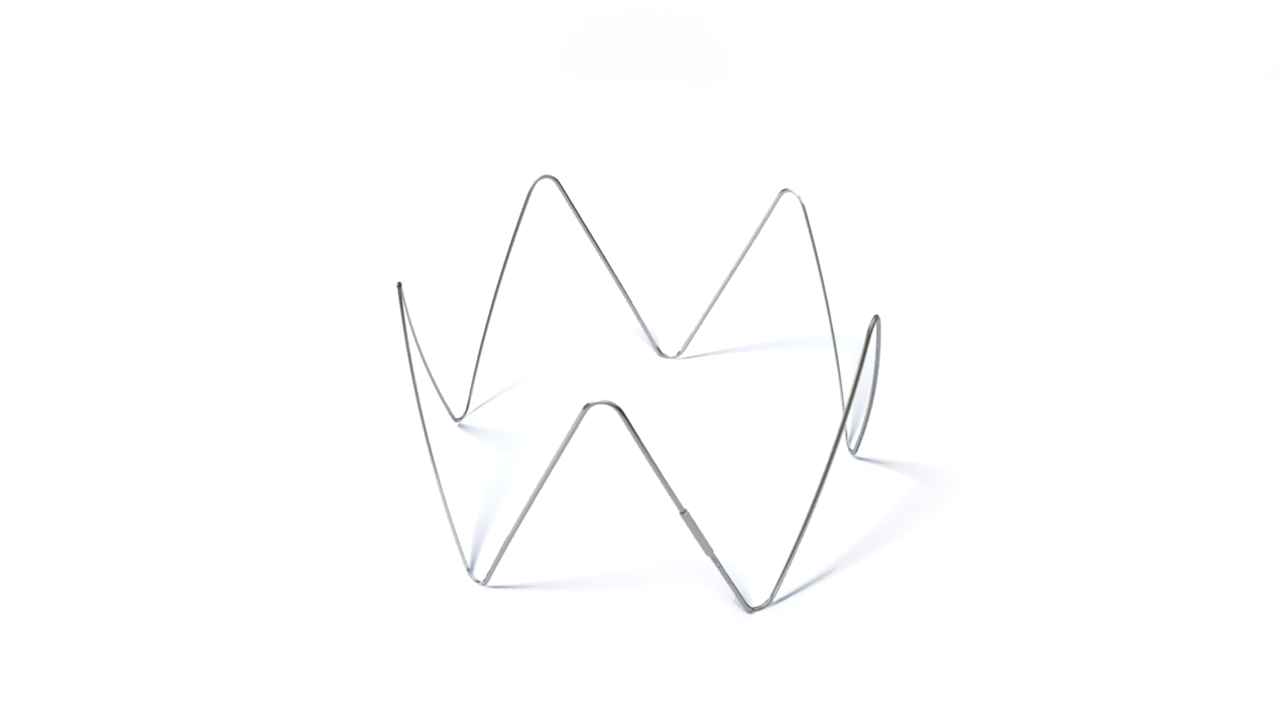

Crown with crimp

.png)

Double diamond, strand

.png)

Double hook, twisted

.png)

Folded ends, flat wire

.png)

Loop, twisted with hypotube

.png)

Single hook, strand

.png)

U-shape with beaded ends

We use various techniques to improve the surface quality of our material and ensure that our material is free of any visible debris or foreign particulates. For more information on our cleaning processes please contact your Fort Wayne Metals Representative.