R&D

- Jun 1, 2015

A Fresh Take on Composite Wire Design

J.E. Schaffer, Ph.D., Senior Research and Development Engineer

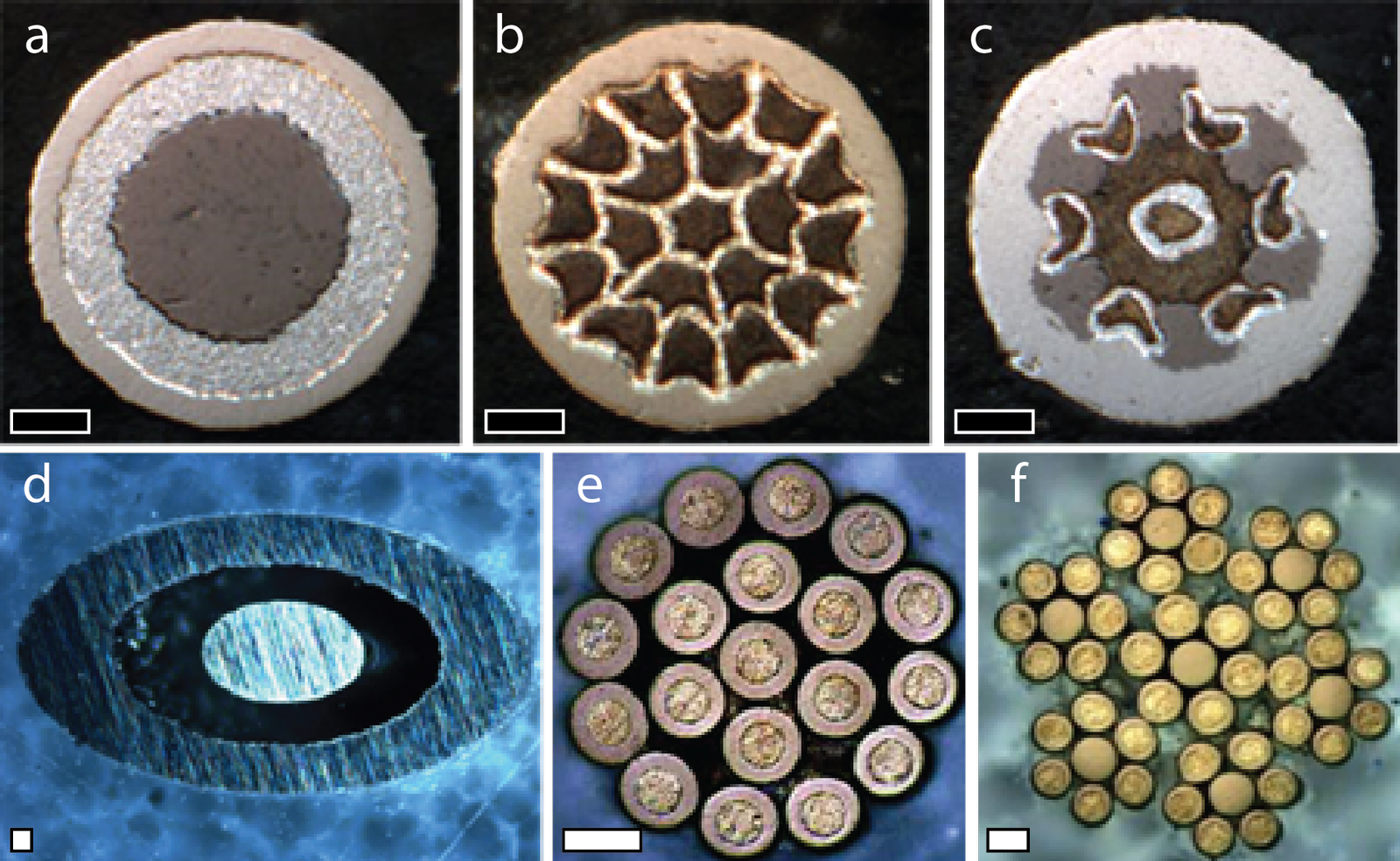

Fort Wayne Metals is a designer’s toolbox, for high performance wire composites. You may know that Fort Wayne Metals has been in the business of providing effective DFT® composite wire solutions for more than 30 years. These solutions end up in devices that require a combination of properties not possible in mono-metals, like high fatigue with electrical conductivity (35N LT-DFT-Ag) or superelasticity with high relative x-ray-opacity (NiTi-DFT-Pt). You may not know that there are many metallic and even non-metallic composite wire designs that have been conceived and successfully executed at a FWM. Some of these designs, such as composite microcables (Fig. 1e, 1f), have developed deep commercial success in the medical bioconductor market. Other designs, such as complex metal matrices (Fig. 1b, 1c) and hybrid designs (Fig. 1d) have yet to exceed prototype phase research. Many other composite designs are under active investigation within FWM Research & Development. This discussion and the wire images below are provided as a sneak peek into the wide world of composite wire possibilities at FWM. For more information, please contact: [email protected].

Figure 1 – Actual wire-section examples of (a) Fort Wayne Metals DFT® Wire comprising a highly corrosion resistant platinum-iridium shell, high strength 35N LT® mid wall and high conductivity tantalum core element; (b) metal filament matrix composite incorporating a platinum shell over a fatigue-resistant array of 35N LT-silver elements; (c) metal filament matrix composite incorporating more than six distinct elements (d) coaxial isolated core wire with non-metal insulation; (e) a 1x19 strand of 35N LT-DFT®-41%Ag wire elements; and (f) a 7x7 cable comprising sub-25 µm DFT outer elements with mixed monolithic 35N LT elements for strength enhancement.

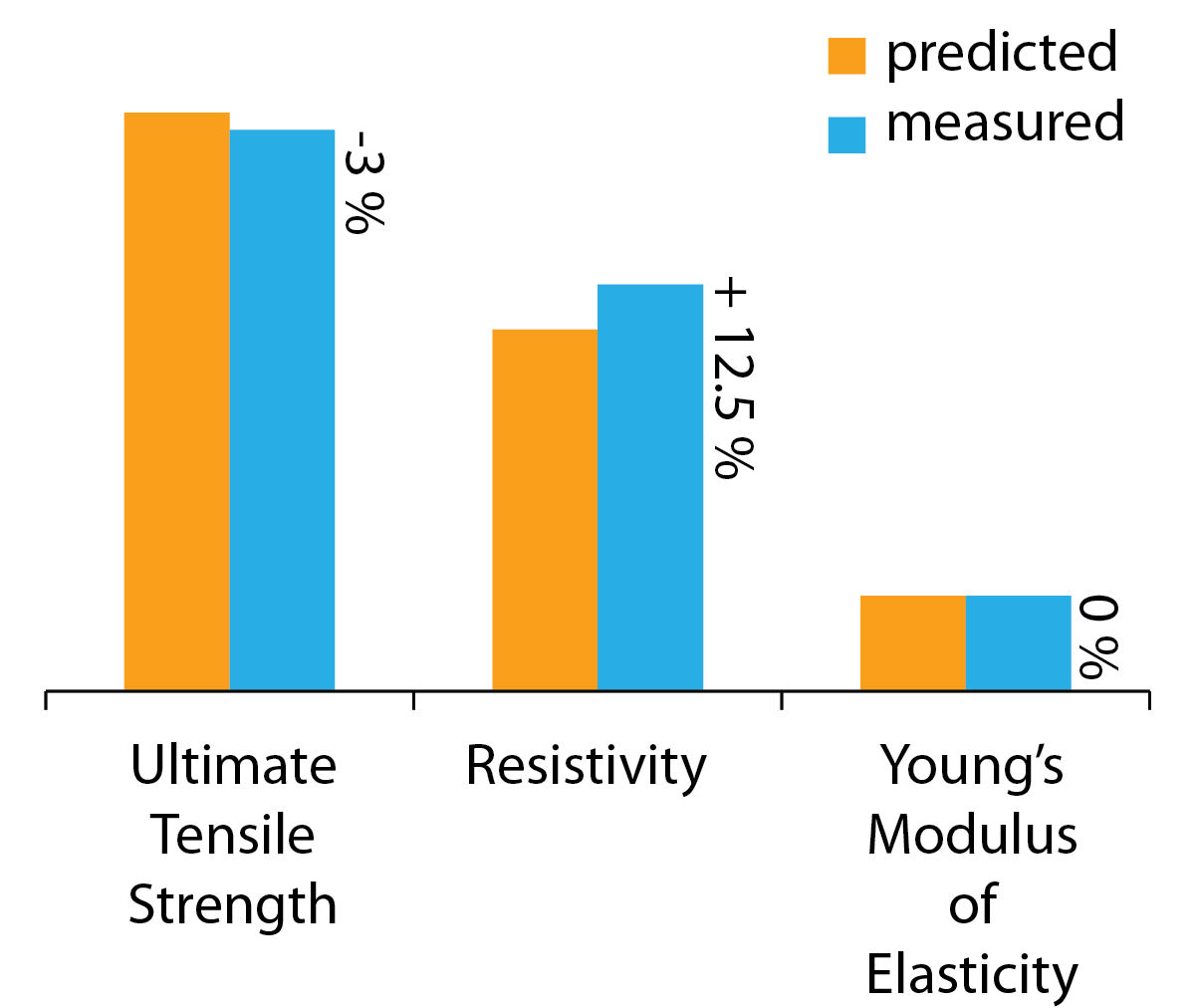

Figure 2 – FWM is able to predict the mechanical and electrical properties of metal matrix composite wires using extensive historical data. Predictions must take into account target thermo-mechanical processing, alloy type, and chemical interactions. Results shown above provide actual measurements in relative units for the Ø 125 µm composite wire given in Fig. 1c.