Understanding the benefits

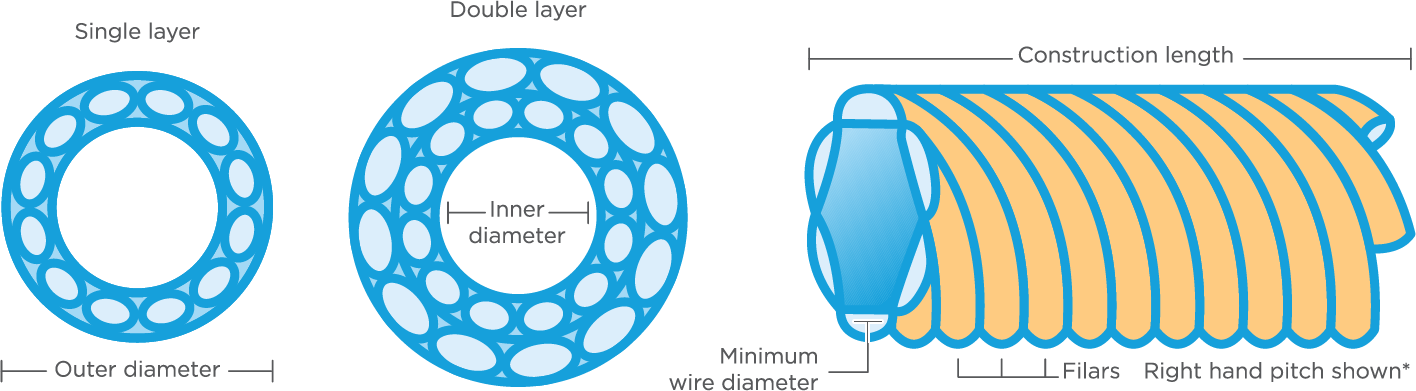

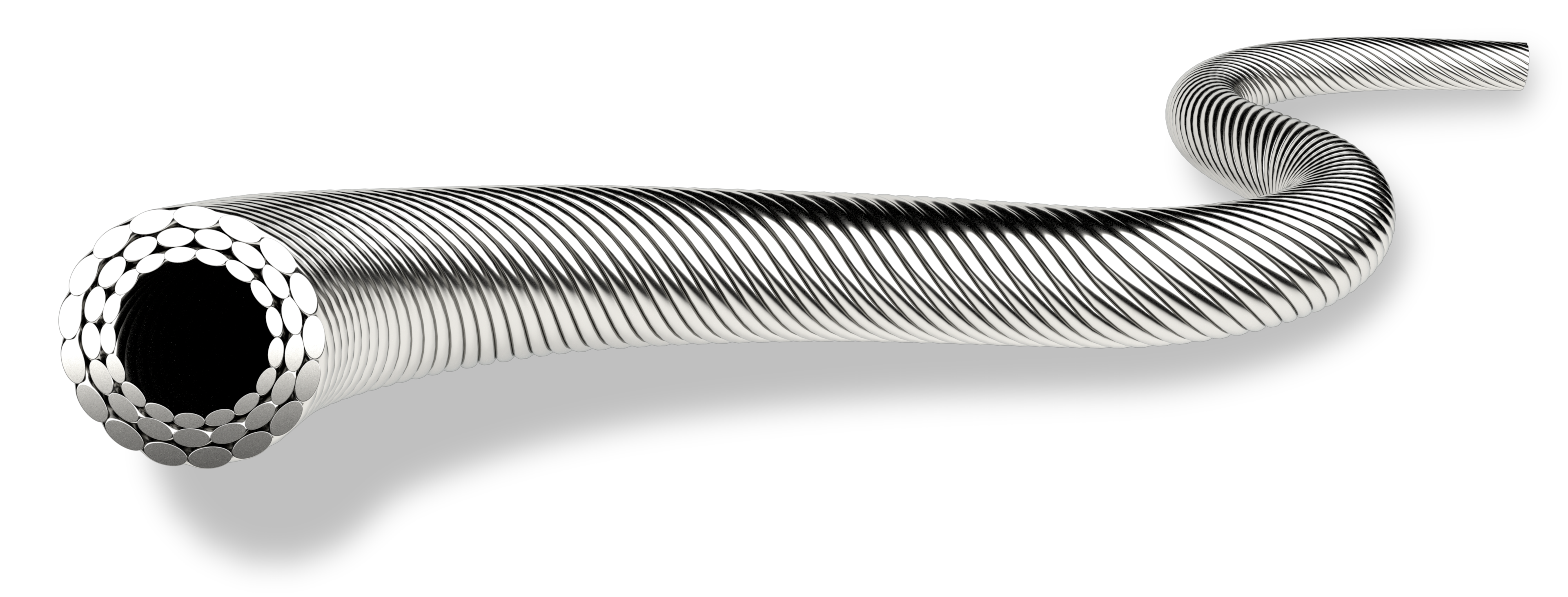

Certain applications require higher performance than unifilar or even multi-filar coil can provide. By selecting single, double, or triple layer and by adjusting filars per layer, filar diameters, and pitch direction, HHS® tube, our version of a torque coil, can be customized for flexibility, torque, and rotational control. HHS® highly engineered multi-filar coil can be customized for flexibility, torque, and rotational control.

| Characteristics | HHS® tube | Coil | |

| Unifilar | Multifilar | ||

|

Torque |

Excellent | Poor | Good |

|

Windup (low) |

Good | Poor | Poor |

|

Whip |

Excellent | Excellent | Excellent |

|

Pushability |

Excellent | Excellent | Good |

|

Elongation resistance |

Excellent | Poor | Good |

|

Compression (%) |

Good | Excellent | Poor |

|

Hoop strength |

Good | Excellent (Tight wound) |

Good |

|

Wall thickness |

Good | Excellent | Excellent |

Design specifications

What makes HHS® tube so versatile is its ability to be customized to your specifications. Below are the standard parameters for design, but we're always open to conversations about products that push the current limits.

- Inside diameter 0.0762 mm to 2.2098 mm [0.003 in to 0.087 in]

- Outside diameter 0.127 mm to 4.064 mm [0.005 in to 0.160 in]

- Minimum Filar Diameter/Thickness 0.0254 mm [0.001 in]

- Filars Up to 18

- Filar Shape round or flat

- Layers 1 to 3

- Pitch direction left, right (pitch direction generally alternates each layer)

- Length up to 120" (depending on construction)

HHS® tube can be customized to meet your design specifications. Changing one specification can impact others. For example, filar size must decrease to accommodate more layers without increasing the overall diameter but allows for more filars to be stranded. Talk to your Sales Representative to explore the possibilities.

Typical end uses

While HHS® tube's exceptional characteristics allow it to serve any number of applications, we've seen our customers use it in:

- Bioconductors

- Catheter devices

- Delivery systems

- Endovascular devices

- Minimally invasive tools

- Neurological components

- Urological tools

- Cardiovascular devices

Materials

We can leverage our knowledge of materials and wire drawing processes to customize HHS® hollow torque strand to fit your applications. The most commonly used materials include:

- 304V stainless steel for high strength

- 316LVM stainless steel for improved ductility and corrosion resistance

- 35N LT™ alloy for fatigue life

- Nitinol for shape set parts

Additional capabilities

Your custom-made HHS® tube can undergo a number of additional processing steps to further tailor it to your needs.

End terminations

End terminations are customized to enhance the durability and functionality of wires in highly demanding applications. They help reduce fraying or breakage from vibrations, movement, or other mechanical stresses.

|

Shear cut A highly efficient end termination, it is widely used if ends will be removed or are unimportant to additional processing. Individual filars may shift during shipping and handling. |

|

|

EDM cut This square cut enables additional processing. Individual filars may shift during shipping and handling. Accompanied by laser welding for optional end termination. |

|

|

Band weld + EDM cut A square cut with filars secured in place. |

|

|

Band weld + EDM cut + face weld Square cut with filars secured in place and all layers mechanically engaged, with slight break possible on inner diameter and/or outer diamter. |

|

We offer a wide range of end termination capabilities beyond the four highlighted above. Explore the list below and contact your Sales Representative for technical support in selecting the right end termination for your product.

Get a performance boost

HHS® tube delivers exceptional mechanical performance for demanding applications. Connect with our technical experts to find the right configuration that fits your needs.

Unable to load the form? Click the button below: