When flexibility meets strength, you get superelastic Nitinol—built to bend without breaking. Superelastic Nitinol's phase transformation in environments cooler than body or room temperature makes these grades more common in medical devices or other lower temperature applications.

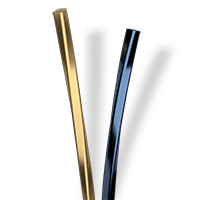

Superelastic Nitinol grades

NiTi #1 is commonly used for applications requiring superelasticity at room and body temperature. Typical applications include guidewires, stents, stylets, forming mandrels, stone retrieval baskets, and orthodontic files.

NiTi #2 is a ternary grade of Nitinol containing additions of chromium (0.2-0.3% Cr by weight) and is often used in applications requiring increased loading and unloading plateau stresses and decreased transformation temperatures.

NiTi #3 is a ternary grade of Nitinol containing additions of cobalt (1.0-2.0% Co by weight) and is often used to maximize loading and unloading plateau stresses over other Nitinol grades. Decreased transformation temperatures also allow this grade of Nitinol to remain superelastic in colder temperature applications.

NiTi #4 has the warmest transformation temperatures of our superelastic grades, resulting in decreased modulus and plateau stresses and improved fatigue performance at room and body temperatures when compared to other superelastic Nitinol grades with equivalent previous cold work and heat treatments.

NiTi #9 is the coldest grade of binary Nitinol that we offer and is used for applications requiring superelasticity at colder temperatures.

After an appropriate heat treatment, superelastic Nitinol will accommodate strain of up to 8% in tension without significant permanent deformation, when tested at room temperature, which is above the transformation temperature of the material.

All binary Nitinol grades meet the chemistry requirements set forth by ASTM F2063 for use in surgical implants.

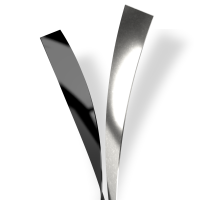

Nitinol products and solutions

Our range of customizable Nitinol products, from flat wire to complex custom shapes, can help advance your cutting-edge projects. And with advanced capabilities like DFT® wire, HHS® tube, and shape-set parts, we're equipped to deliver precision-engineered solutions for the most demanding applications. Partner with us to explore the full potential of Nitinol for your applications.

Mechanical properties

Nitinol offers seemingly endless possibilities. You can use the following information to learn more about superelastic Nitinol, and the markets we serve.

|

Superelastic (i.e. straight annealed) |

|||||

|

Product |

NiTi #1 | NiTi #2 | NiTi #3 | NiTi #4 | NiTi #9 |

| Ingot Aₛ |

-35 °C to -10 °C |

-65 °C to 5 °C [-85 °F to 41 °F] |

-95 °C to -65 °C [-139 °F to -85 °F] |

-10 °C to 10 °C [14 °F to 50 °F] |

≤ -35 °C [≤ -31 °F] |

| UTS |

1241 MPA |

1378 MPa [200 ksi] |

1241 MPa [180 ksi] |

1241 MPa [180 ksi] |

1103 MPa [160 ksi] |

| Elongation |

> 10% |

> 10% | > 10% | > 10% | > 10% |

| Upper Plateau |

> 483 MPa |

> 552 MPa [> 80 ksi] |

> 689 MPa [> 100 ksi] |

> 448 MPa [> 65 ksi] |

> 517 MPa [> 75 ksi] |

| Lower Plateau |

> 138 MPa |

> 207 MPa [> 30 ksi] |

> 414 MPa [> 60 ksi] |

> 48 MPa [> 7 ksi] |

> 172 MPa [> 25 ksi] |

| Active Aᶠ |

10 °C to 18 °C |

0 °C to 18 °C [32 °F to 64 °F] |

-20 °C to -10 °C [-4 °F to 14 °F] |

14 °C to 22 °C [57 °F to 71 °F] |

-10 °C to 5 °C [14 °F to 41 °F] |

| Notes |

Permanent set < 0.5% after strained to 8%. Results are typical for round wire diameters from 0.0254 mm to 1.02 mm [0.001 in to 0.04 in]. All mechanical testing conducted at 22 °C ± 2 °C [71.6 °F ± 3.6 °F]. Please note that a correlation study may be required to switch test methods on an existing part. |

||||

| Cold worked (i.e. Hard, as drawn) | |||||

|

Product |

NiTi #1 | NiTi #2 | NiTi #3 | NiTi #4 | NiTi #9 |

| Ingot Aₛ |

-35 °C to -10 °C |

-65 °C to 5 °C [-85 °F to 41 °F] |

-95 °C to -65 °C [-139 °F to -85 °F] |

-10 °C to 10 °C [14 °F to 50 °F] |

≤ -35 °C [≤ -31 °F] |

| UTS |

1379 MPa |

1655 MPa [240 ksi] |

1379 MPa [200 ksi] |

1379 MPa [200 ksi] |

1379 MPa [200 ksi] |

|

Elongation |

> 4% |

> 4% | > 4% | > 4% | > 4% |

| Notes | Permanent set < 0.5% after strained to 8%. Results are typical for round wire diameters from 0.03 mm to 1.02 mm [0.001 in to 0.04 in]. All mechanical testing conducted at 22 °C ± 2 °C [71.6 °F ± 3.6 °F]. Please note that a correlation study may be required to switch test methods on an existing part. Data contained herein is for reference only. If you require specific thermal and/or mechanical properties, please specify when requesting quotation. |

||||

|

Superelastic (i.e. straight annealed) tested at 37°C [98.6°F] |

|||||

|

Product |

NiTi #1 | NiTi #2 | NiTi #3 | NiTi #4 | NiTi #9 |

| Ingot Aₛ |

-35 °C to -10 °C |

-65 °C to 5 °C [-85 °F to 41 °F] |

-95 °C to -65 °C [-139 °F to -85 °F] |

-10 °C to 10 °C [14 °F to 50 °F] |

≤ -35 °C [≤ -31 °F] |

| UTS |

1241 MPA |

1378 MPa [200 ksi] |

1241 MPa [180 ksi] |

1241 MPa [180 ksi] |

1103 MPa [160 ksi] |

| Elongation |

> 10% |

> 10% | > 10% | > 10% | > 10% |

| Upper Plateau |

> 552 MPa |

> 621 MPa [> 90 ksi] |

> 758 MPa [> 110 ksi] |

> 552 MPa [> 80 ksi] |

> 552 MPa [> 80 ksi] |

| Lower Plateau |

> 207 MPa |

> 276 MPa [> 40 ksi] |

> 483 MPa [> 70 ksi] |

> 138 MPa [> 20 ksi] |

> 207 MPa [> 30 ksi] |

| Active Aᶠ |

10 °C to 18 °C |

0 °C to 18 °C [32 °F to 64 °F] |

-20 °C to -10 °C [-4 °F to 14 °F] |

14 °C to 22 °C [57 °F to 71 °F] |

-10 °C to 5 °C [14 °F to 41 °F] |

| Notes |

Permanent set < 0.5% after strained to 8%. Results are typical for round wire diameters from 0.0254 mm to 1.02 mm [0.001 in to 0.04 in]. All mechanical testing conducted at 37 °C ± 1°C [98.6°F ± 1.8°F]. Please note that a correlation study may be required to switch test methods on an existing part.

Data contained herein is for reference only. If you require specific thermal and/or mechanical properties, please specify when requesting quotation.

|

||||

The markets we serve

From coronary stents and pacemakers to deep brain stimulators and archwires, our advanced Nitinol solutions are tailored to the unique material performance needs in demanding medical devices across a variety of markets.

Unable to load the form? Click the button below: