Understanding the benefits

You can customize SLT® wire for your intended application by selecting one of the four distinct types. The chart below will compare the four types, please read on to learn more.

Type 1

Eliminate manufacturing process steps and the need for additional equipment in already straight wire.

Typical end uses:

- Braiding mandrels

- Dental probes

- Staples

Straightness variance 25.4 mm per 304.8 mm [1.00 in per 12.00 in] measured per ASTM F2819

Packing specifications wire on a spool

Minimum hub size 220x wire diameter

Type 2

Eliminate the need for mechanical straightening and leverage rotary-mark-free surface with no need for further polishing.

Typical end uses:

- Micro-needles

- Needles

- Point coiling

- Staples

Straightness variance 2.997 mm per 304.8 mm [0.118 in per 12.00 in] measured per ASTM F2819

Packing specifications wire on a spool or cut to length

Minimum hub size 300x wire diameter

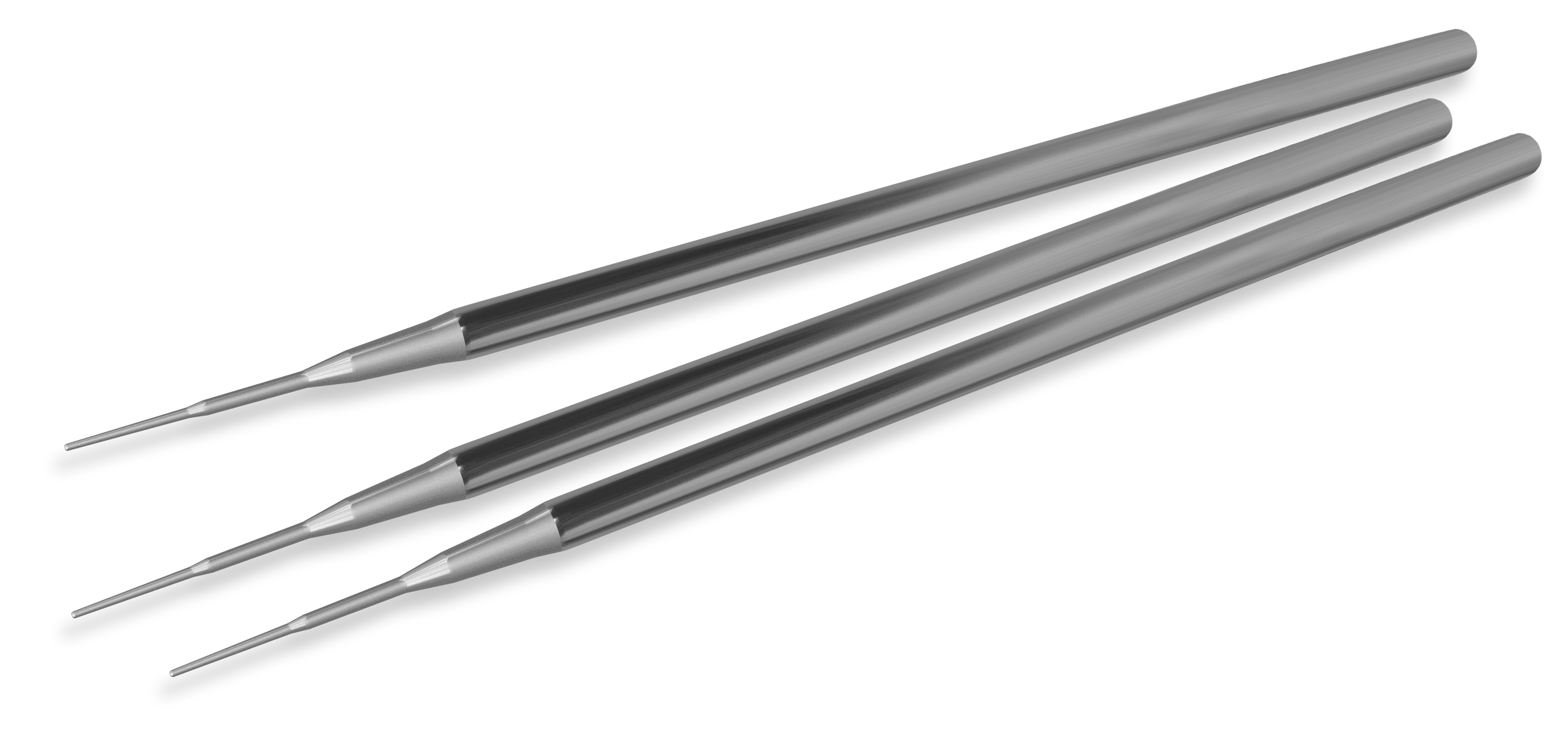

Type 3

Eliminate the need to straighten and allows removal of up to 90% of the cross-sectional area by taper grinding without requiring heat treatment.

Typical end uses:

- Embolic filters

- Endoscopes

- Guidewires

- Orthodontics

- Suture needles

Straightness variance 0.508 mm per 304.8 mm [0.02 in per 12.00 in] measured per ASTM F2819

Packing specifications wire on a spool or cut to length

Minimum hub size 400x wire diameter

Type 4

Leverage 1:1 torque transmission and remove up to 95% of the cross-sectional area by deep taper grinding without requiring additional heat treatment or resulting in pigtailing.

Typical end uses:

- Endoscopes

- Guidewires

- Other precision applications

- Steerable PTCA

Meets ASTM F2819 standards

Straightness variance 0.254 mm per 304.8 mm [0.01 in per 12.00 in] measured per ASTM F2819

Packing specifications cut to length only

Design specifications

Use the chart below to discover the material condition, surface finish, and diameter possibilities for each type of SLT® wire.

| SLT® wire | Condition | Surface finish | Available size(s) | |

| mm | in | |||

| Type 1 |

Half Hard |

Bright | 0.0381 - 1.3716 | 0.0015 - 0.054 |

|

Hyten |

0.0508 - 0.8890 | 0.0020 - 0.0350 | ||

| Type 2 |

Hard |

Bright | 0.0508 - 1.0033 | 0.002 - 0.0395 |

|

Hyten |

0.0508 - 0.8890 | 0.002 - 0.0350 | ||

| Type 3 |

Hard |

Bright | 0.0508 - 1.0033 | 0.0020 - 0.0395 |

| Ultra Spring |

0.0508 - 0.9398 |

0.002 - 0.0370 | ||

| Hyten |

0.0508 - 0.8890 |

0.0015 - 0.0350 | ||

| Type 4 |

Spring |

Bright |

0.1981 - 0.8712 |

0.0078 - 0.0343 |

|

Hyten |

0.1981 - 0.7620 | 0.0078 - 0.0300 | ||

Additional processing capabilities

No matter how you need your SLT® wire, we're here to make sure you get exactly what you need. We can supply SLT® wire in cut lengths or on a spool and provide additional processing, such as:

How SLT® wire stacks up

Fort Wayne Metals conducted an extensive comparison test of its SLT® wire against two competitors that both produce rotary straight and cut wire material. The study measured the material performance of the wire samples.

Improve performance and reduce downtime with SLT® wire. Contact our technical team to find the right option for your needs.

Unable to load the form? Click the button below: