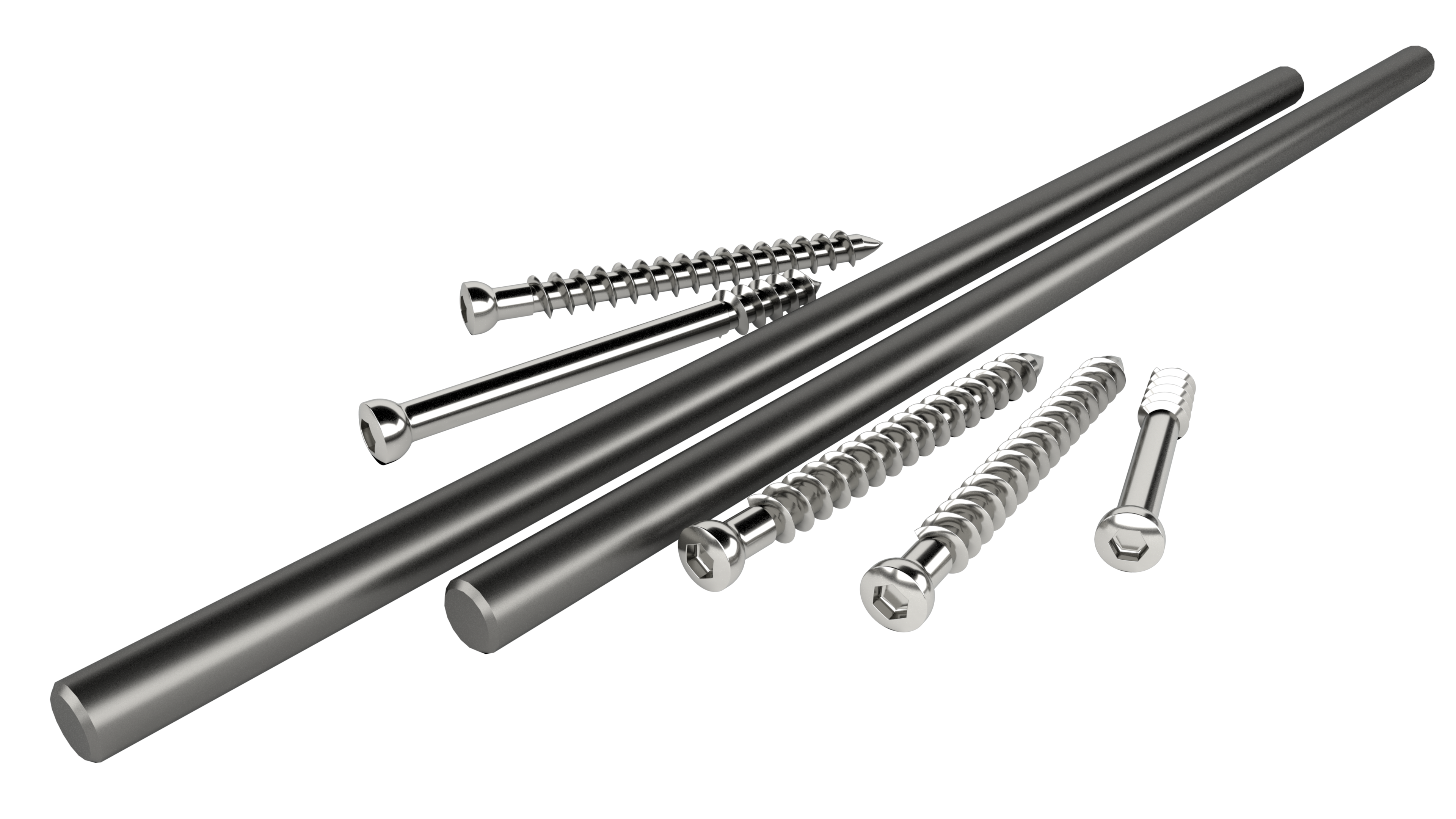

Understanding bar products

Bar is typically produced as centerless ground, offering a straight product with tight tolerances and a smooth, polished surface. Bar products are manufactured to meet your specifications for tensile strength, yield strength, diameter tolerance, and length. Additionally, we offer precision-drawn bar. Depending on the alloy, bar can offer strength, corrosion resistance, and good biocompatibility, making this product remarkably adaptable. We also provide dedicated engineering support every step of the way.

Size ranges

Processing capabilities can differ depending on the alloy, so check with your Sales Representative about the possibilities for your bar product.

- Diameter 0.559 mm to 12.7 mm [0.022 in to 0.500 in]

- Length 304 mm to 3708 mm [12 in to 146 in]

- Custom tolerances available upon request

Surface Ra (roughness average)

- Stainless steel: <0.4 µm [16 µin]

- Centerless ground and polished

- High-performance alloys: <0.4 µm

[16 µin]- Centerless ground and polished

- Titanium: <0.8 µm [32 µin]

- Centerless ground and polished

- Mill finish: <1.6 µm [64 µin]

- Applies to all carbide drawn products

Additional capabilities

- End treatments

- Chamfered ends

- Specialized quality testing

- Eddy current testing

- Ultrasonic testing

Surface finish options

- Bright finish

- Mill finish with rough, matte surface

- Centerless ground with polished, smooth surface

Design specifications

The first step to designing bar products is choosing the right alloy for your application. You can learn more about available alloys by clicking the pages below.

Typical end uses

Our customers have used bar products to make:

- Dental implants

- Orthopaedic guidewires

- Orthopaedic screws

- Pins

- Spinal rods

- Springs

- Fasteners

- Conductors

Unable to load the form? Click the button below: